Liquid Injection Waterproofing and Sealing

We Stop Water

ANYWHERE; ABOVE OR UNDERGROUND

Liquid Waterproofing Branches

WESTERN AND EASTERN CAPE

Tania Verheem

+27(0)82 330 2089

WhatsApp Text Recommended

+27(0)82 330 2089

ObscureCLWP

GAUTENG

Willem Visser

Valerie Erasmus

+27(0)12 205 1812

+27(0)82 415 2081

+27(0)72 296 9372

WhatsApp Text Recommended

+27(0)82 415 2081

ObscureLWP

ObscureWILL

KWAZULU-NATAL

Debbie Barnard

+27(0)82 962 2183

+27(0)82 415 2081

WhatsApp Text Recommended

+27(0)82 962 2183

ObscureDebbie

Liquid Waterproofing Group

About Us

The Liquid Waterproofing Group operates as a specialist company and is able to deal with all civil engineering and mining water leakages of all types derived from a uniquely experienced background of the toughest engineering environments.

We have an experienced engineering team with an exceptional level of expertise in concrete technology and construction, water control, support and stabilisation techniques.

By retaining a specialist approach, the company is able to deliver on time and within budget and has strict quality controls over all aspects of the operations.

All our components are tried and tested under extreme pressures with high volume water flow. These very high pressures are only limited by the grout pumps itself. Pressures of up to 50 Bar can easily be achieved.

Core Competencies

Leaders in modern technology solutions since 1999.

The Liquid Waterproofing Group developed water-based polymer components to stop water in mines and subsequently refined our solutions for structural applications.

Don't be misled.

Not all 'injection waterproofing systems' are equal.

Providing proven solutions for failed traditional waterproofing methods.

Addressing the sources of the ingress problem, the results can be far more accurate and measured.

Far less intrusive remedial solutions to existing water ingress.

Much quicker compared to alternative conventional waterproofing. We seal unwanted water with little to no disruptions to our client's operations, cost effectively and without delays.

Providing our clients with technically advanced quality products and services while complying with all health, environmental and safety regulations.

Applications and Services

Chemical Grouting

MINES

TUNNELS

SUBWAYS

Re-Grouting

Remedial Grouting

Curtain Grouting

Back Wall Grouting

Reactive Grouting

Injection Waterproofing

Civil Engineering

Commercial

Residential

Basements, Wine Cellars, Lift Shafts, Knock Tanks, Retainer Walls, Cavity Walls, Rising Damp, Silos, Concrete Cracks, Honeycombing in Concrete, Spalling in Concrete, Construction Joints, Expansion Joints, Aluminium Window and Door Frames

Polyurea Spray Coatings

SEAMLESS HOT SPRAYED

Waterproofing

Corrosion Protection

Steel Reinforcement

Isolation

Abrasion Protection

Click to view..

Click to view..

Completed Installations

Gautrain Tunnel Sealed

Gauteng South Africa

Liquid Waterproofing was contracted to seal the water leakage in the Gautrain tunnel system.

The successful sealing of the Gautrain tunnel in the vicinity of Park Station allowed the station to open for business.

This includes the tunnels from Park Station to Rosebank Station, Rosebank Station to Sandton Station and Sandton Station to Marlboro Station.

.jpeg)

Ghaghoo Mine Sealed

Botswanna

"Interestingly, the company comes highly recommended by Clifford Elphick, CEO of diamond producer Gem Diamonds, who, after unsuccessful attempts at sealing a massive fissure at its new Ghaghoo diamond mine in Botswana, turned to Liquid Waterproofing for a solution."

SA MINING JANUARY/FEBRUARY 2016

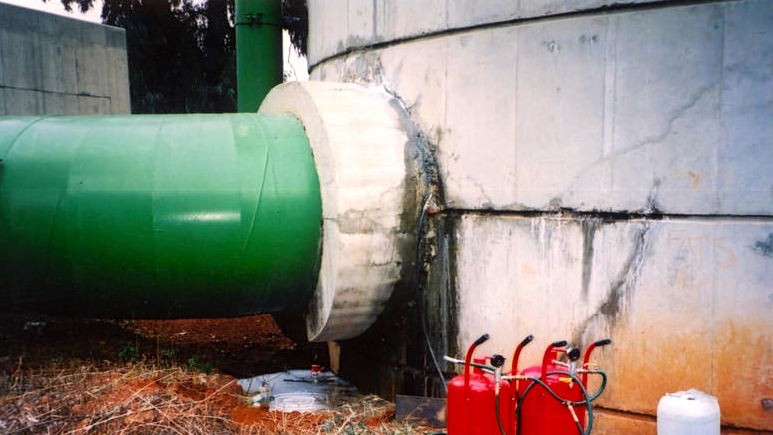

Anglo Platinum

Amandelbult

Various fissures have been intersected by cover drilling decanting approximately 2500 to 8000 litres per hour at pressures of approximately 11 bar through a 50mm casing pipe. The highest pressure encountered was 27 bar.

All these fissures have been pre-sealed with chemical grouting through pre-drilled holes in the face which intercepted the fissure. Grouting distance varied between 8 and 15m. ...

Mopani Mine Zambia

Mindolo Shaft

The development in the lowest section of the mine, stretched through a waterbearing aquifer with water temperature measuring 60 to 70 degrees Cels.

Cementation of the drilled holes took to long to set and progress was too slow.

Liquid Waterproofing undertook the chemical grouting under extreme conditions and sealed the water as development continued.

Case Studies

The Last Twenty Years

Mines and Tunnels

Ghaghoo Mine Botswanna

Anglo Platinum - Amandelbult

Mopani Mine Zambia - Mulfilera Shaft

De Beers Finsch Mine

Gautrain Tunnel

Impala Platinum Mine

BHP Billiton - Wessels Mine

Interestingly enough during this sealing exercise another area that had been water stricken some 110m above had also dried up and is no longer a problem

N Conley, Geotechnical Officer, De Beers (Finsch Mine)

On all of these occasions Liquid Waterproofing have been successful in effectively sealing these water intersections and allowed for the development of the haulages and crosscuts to continue in a timeous fashion

Adrian Colloty, Shaft Geologist Anglo Platinum (Amandelbult)

Liquid Waterproofing

Liquid Waterproofing